GTAW/TIG Gas Tungsten Arc Welding/Tungsten Inert Gas Welding

Why take this course?

🚀 Course Title: [GTAW/TIG] Gas Tungsten Arc Welding/Tungsten Inert Gas Welding

🛠️ Headline: Master Piping & Welding in Construction and Maintenance for Refinery, Power Plants, Pipeline, Offshore & Nuclear Energy

Course Overview:

Welcome to the comprehensive GTAW/TIG Gas Tungsten Arc Welding/Tungsten Inert Gas Welding course designed specifically for working professionals in the Oil & Gas industry. This course, instructed by the esteemed MANSUKH SATASHIY, is tailored for Mechanical Engineers, QA/QC Engineers, Welding Engineers, and NDT (Non-Destructive Testing) Engineers who are involved in shutdowns, maintenance, production, and more.

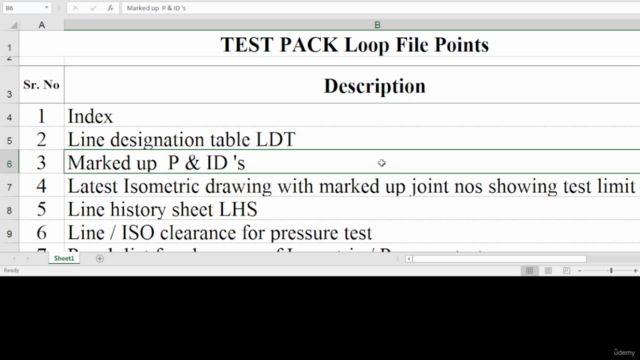

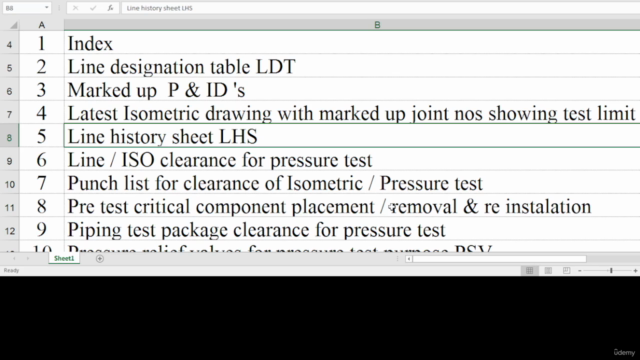

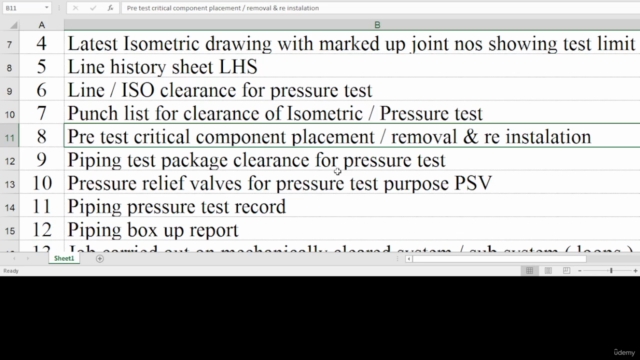

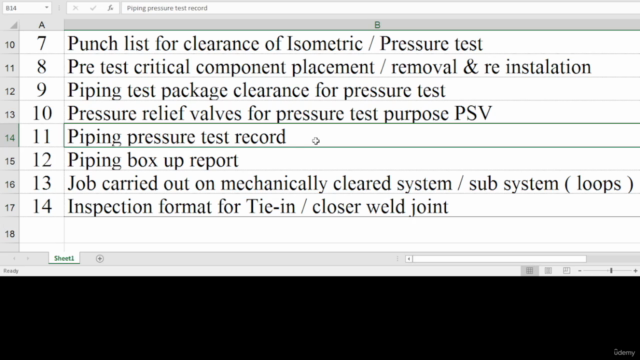

By completing this course, you will not only enhance your technical skills but also improve your interview abilities and boost your confidence. You will delve into the nuances of code, specifications, procedures, formats, ITP (Inspection Test Plans), QAP (Quality Assurance Plans), Isometric Drawings, P&ID (Piping & Instrumentation Diagrams), PFDs (Process Flow Diagrams), GA (General Arrangements), Drawings, Audit Plans, Training Plans, NDT Reports, Loop Files, Test Packs, and Test Circuits.

Key Learning Areas:

-

Knowledge Enhancement: Gain a deeper understanding of code, specifications, and procedures essential for effective piping and welding operations.

- Master ITP, QAP, and various drawing types, including P&ID, PFDs, GA, and more.

- Learn about Audit Plans, Training Plans, NDT Reports, Loop Files, Test Packs, and Test Circuits.

-

Operational Mastery: Acquire skills in Warehouse Management, Fit up, Welding, Fabrication, Erection, NDT, Blasting, Painting, Hydro test, Punch Point, Cardboard Blasting, Insulation, Oxygen Service Cleanliness, Box-up, and Hand Over.

- Understand the importance of Preservation and Handover processes.

- Learn about continuous improvement processes and soft skill development for behavior change.

-

Safety and Best Practices: Ensure compliance with safety standards and regulations through Tool Box Talks and House Keeping.

- Emphasize on Corrosion Prevention, Shutdown Management, Maintenance Dossier, and Safety Measures.

Become an Expert in the Oil & Gas Industry:

-

NDT Techniques: Learn the intricacies of Dye Penetrant testing, Magnetic Particle testing, Radiography testing, Ultrasonic testing, Visual testing, Radiography Film review, and more advanced techniques like Digital thickness test, Phased array Ultrasonic testing, and Time of Flight Diffraction (TOFD) Ultrasonic testing.

-

Knowledge in ASME Code: Understand the critical role of the ASME code in welding and piping, and how it applies to various projects like refineries, petrochemical complexes, cross-country pipelines, well pads, and offshore platforms.

-

Welding & Piping Knowledge: Acquire extensive knowledge in Welding Process, Piping, NDT, Blasting and Painting, Corrosion rate calculation, Hydro test, Pneumatic Test, and Line History sheet management.

🔥 Why Take This Course?

- Expert Guidance: Learn from an experienced instructor with a wealth of knowledge in the field.

- Real-World Application: Apply what you learn directly to your work in construction and maintenance scenarios.

- Skill Set Expansion: Broaden your skill set, making you a valuable asset to any team.

- Career Advancement: Stand out in the job market with advanced knowledge and practical skills.

- Comprehensive Coverage: This course covers everything from technical procedures to soft skills that are crucial for success in the industry.

🎓 Enroll now and take the first step towards becoming an expert in Oil & Gas piping and welding with a focus on NDT, ensuring safety, efficiency, and excellence in your professional journey. Let MANSUKH SATASHIY guide you through this transformative learning experience! 🌟

Course Gallery

Loading charts...